Do you need to cut through Plexiglass but don’t know where to start? This comprehensive guide will show you the dos and don’ts of cutting Plexiglass with a jigsaw. You will learn the right tools and techniques needed to not only finish the job, but make sure it is done safely.

So put on your safety glasses, grab your jigsaw, and let’s get to work!

Plexiglass, also referred to as acrylic, is a plastic material that is both strong and lightweight and can be used as a substitute for glass in many applications. It has many advantages including ease of use and affordability. Nowadays, a jigsaw can be used to cut Plexiglas with great precision.

It requires a bit more finesse than cutting aluminum or steel because Heat build-up can cause chipping and cracking. In order to cut Plexiglas with the least amount of flaws, it is important to follow certain procedures.

The following guide outlines dos’s and don’ts when cutting Plexiglass with a jigsaw so that you can get consistently clean results each time.

Explanation of what plexiglass is

Plexiglass is a lightweight, optically transparent material that is widely used for its temperature resistance, low-friction surface, and superior optical clarity. Plexiglass is composed of polymethylmethacrylate (PMMA), also known as acrylic or acrylic glass. This versatile material is often used in a wide range of creative projects and industrial applications due to its lightweight, shatterproof properties and affordability.

Plexiglass can be cut to fit nearly any dimension without sacrificing the durability of the material. The most common way of cutting plexiglass is with a jigsaw. However, there are many important factors that you should take into consideration before cutting plexiglass with a jigsaw. To ensure a successful project and protect your tools from damage, read this guide on what you should do (dos) and should not do (don’ts) when cutting plexiglass with a jigsaw!

Importance of knowing the dos and don’ts when cutting plexiglass with a jigsaw

Knowing the dos and don’ts of cutting plexiglass with a jigsaw is of critical importance. First, plexiglass is a unique material that requires special considerations compared to other materials when cutting. Plexiglass is subject to generating heat while using the jigsaw, which can cause warping or cracking over time. Additionally, plexiglass tends to shatter upon impact if it has been cut too fast — thus, speed control is essential when cutting plexiglass with a jigsaw. As such, ensuring that you have the right equipment and setup before beginning work on your project will help ensure safety and successful outcomes.

Aside from proper setup and speed control precautions, there are other important tips to bear in mind when using your jigsaw:

-When possible, clamp or secure your workpiece onto a firm surface – having it move during operation could result in uneven cuts or dangerous materials/particles flying everywhere – Make sure you wear eye protection (preferably safety glasses) whenever operating your jigsaw -Safety first! Read and observe all necessary safety precautions for power tools in general -Start at an angle away from the cutting line so that you can get used to navigating the saw around before coming closer to the material – this will prevent any accidental breakage or damage -Work slowly – this allows more time for cooling periods between cuts -Know how much depth you need for each cut – larger depths require more finesse with controls -Use a steady pressure on each cut – do not increase or decrease pressure as needed

Using these considerations as guidelines while operating your jigsaw should ensure successful results while cutting plexiglass with minimal risk of injury or damage.

Dos

When cutting Plexiglas, remember to always wear safety goggles or safety glasses to protect your eyes from flying chips and dust. Here is a list of tips for best results when cutting with a jigsaw:

- If cutting an acrylic sheet that is thicker than 1/4″ (6mm), use a blade specifically designed for plastics. This type of blade runs cooler and reduces the chance of melting the plastic.

- Use high speed steel (HSS) blades and select one that matches the properties of your workpiece material as closely as possible.

- Choose a blade with teeth that alternate between large gullets and small ones, which ensure adequate cutting performance even through thick materials. Fine-toothed blades should be used for thinner plastics such as polycarbonate or polypropylene sheets.

- Install the saw blade so that it is perpendicular to the material surface to get the cleanest edges without scorching them due to friction heat build-up at turbulence areas while running a jigsaw along curves in parts, particularly complex shapes with many cutlines crossing each other in different directions.

- Use a special coolant spray or liquid solution when sawing materials like Plexiglas rods and/or tubes which are more prone to melt due to their shape and thicknessening during machining process due its nature on heat conduction unlike flat acrylic sheets which have much better thermal capabilities on heat dissipation making flat ones easier than round counterparts even at same thicknessesw cuts outcomes compared between two shapes across same sample inputs after passing tests on both materials solely for comparative purposes only.

Preparing the work area

Before you start cutting, consider a few steps to help ensure a safe and successful project. When working with Plexiglas, it’s important to take the time to properly prepare your work area since this type of plastic tends to produce sharp burrs along the edge of the cuts.

To get started, make sure you are working in an open area that is well-ventilated and free from dust or other debris. Also ensure that there is sufficient lighting so that you can clearly see where you are cutting. It’s recommended that safety glasses be worn throughout the entire process for protection against both flying debris and dust particles that may travel throughout the area.

Lastly, be sure you have a stable platform on which to place your piece of Plexiglas and proper clearance around the area in case sparks or burning plastic occur.

Choosing the right location

When cutting Plexiglass, it’s important to select a suitable space for the job. Due to the potential of small particles and bits of plexiglass being propelled during operation, you should be sure to take certain safety precautions.

Finding a well-ventilated area is beneficial as it will keep dust and debris away from your face and eyes. Working outdoors or in an enclosed garage or shed with an open door are both acceptable options as long as there is adequate air flow and dust collection can easily occur. Additionally, if working in a basement or any area where fumes cannot disperse quickly enough, you should use a respirator or ample ventilation.

Also be sure to wear safety glasses when working with jigsaws to prevent injures from uncontrolled pieces of plexiglass flying due to malfunctioning of the saw’s blades.

Cleaning the work area

Before you start any project involving plexiglass, it is essential to make sure that your work area is clean and free of debris. This will help to protect the material from scratches, dirt and dust. Begin by clearing away any objects that may present a danger to you or the material itself. Put your tools in one area, while organizing any scraps of plexiglass into another. Allocate a space away from the saw to put finished pieces until the time comes for assembly.

Utilize these tips for keeping your work area clean:

- Wear protective gear such as goggles and gloves when working with power tools

- Cover any nearby furniture or walls with plastic or tarps to avoid dirt and debris buildup

- Sweep up excess sawdust after cutting

- Organize all materials and tools systematically

- Clean up spilled cutting fluids immediately with a shop towel

Choosing the right jigsaw blade

One of the most important factors to consider when cutting plexiglass is the type of blade that you use. When selecting a jigsaw blade, keep in mind the following points.

First, use blades specifically designed for plastics or plastics-type materials such as plexiglass. These blades tend to have larger teeth and fewer teeth per inch (TPI) than traditional wood-cutting blades. The larger teeth are designed to cut through the tougher material and provide a cleaner cut edge.

Secondly, select a blade that has a salt-and-pepper pattern on the blade — this will help eliminate chipping on the edge of your cut line due to excessive stress and heat build up in one area of the material.

Finally, choose a jigsaw blade with reverse teeth on one side – this will help prevent splintering during the cutting process and provide you with smoother cuts overall. Finding the right jigsaw blade is key to producing great results when cutting plexiglass – be sure to do some research before purchasing your supplies!

Selecting the right type of blade

Using the wrong type of blade when cutting Plexiglass will most likely result in chipping or cracking. It’s important to select an appropriate blade for the job at hand, as well as considering the jigsaw you are using. There are several different types of blades made specifically for cutting plastic, including blades with teeth that spiral around a center point and those with progressive tooth angles that lessen chipping and cracking.

Make sure you read any accompanying instructions before attempting this project.

Checking the blade’s condition

It’s important to inspect the blade before commencing to cut the material. Check if it’s clean and sharp and be sure to replace it as soon as you notice unusual wear and tear. A sharp blade is a must when working with plexiglass sheets because this provides a precise, clean edge free of splinters or chipping. You should also check if the blade is compatible with plexiglass – the type of material your saw should accept depends on its capabilities. If you use an incorrect saw, it may cause significant damage to your sheets, leaving them cracked or even split open.

Flexible blades – something that most jig saws come equipped with – are ideal for dealing with curved cuts which are necessary when cutting plexiglass sheets since straight edges do not occur naturally when pushing a flat sheet into shape. Do note that blades require frequent replacement in this case because plastic tends to wear them down quickly – be sure to observe your progress during work and pay attention for any signs of blade fatigue immediately in order keep it from damaging the material further by reducing power from overlapping cutting motions.

Marking the cut line

Before you begin the actual cutting of the Plexiglass, it’s important to take some time to mark the cut line you wish to follow. To ensure a straight line, you will want to use a sharp pencil and make several light passes over your mark as desired. Make sure that all lines are drawn as lightly as possible, since any smudges or lines that are too dark could be mistaken for the final cut line.

Once the mark is complete, hold a steel ruler or metal square against it and double-check that it lies exactly along the line. If any corrections need to be made, go ahead and make them with your pencil before continuing.

Measuring and marking the line accurately

Accurate measurements and markings are very important when it comes to cutting a plexiglass piece with a jigsaw. Make sure you take double and triple measurements to be exactly sure of the line you want to cut. Then, use a black marker or a pencil to trace the outline onto the plexiglass for easy reference when cutting.

It is also helpful when tracing the line onto the material if you place masking tape on both sides of the line, so that your tool can easily follow along and make a neat cut along the traced line.

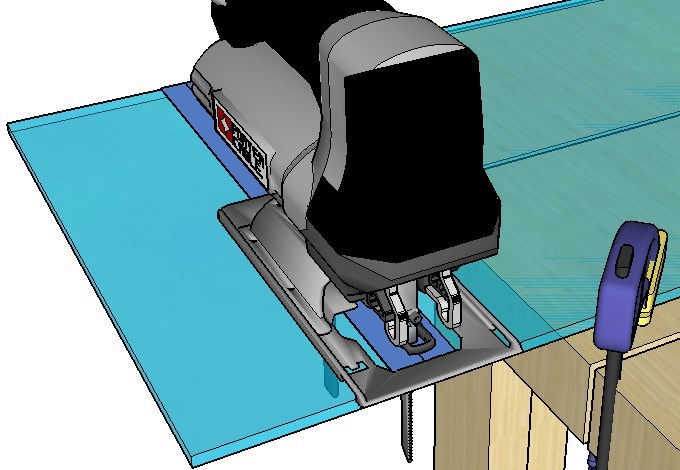

Using a straight edge to guide the saw

Using a straight edge to guide the jigsaw can ensure better accuracy and reduce the chances of breaking or splitting the plexiglass. Consider using a piece of wood clamped to the plexiglass as a guide. This will help the saw move in a straight line and reduce the risk of cracking the material.

It is important that the jigsaw blade match up to the outside edge of your guide so that it cuts in exactly where you want it to. To avoid any chipping or cracking, make sure that your clamps are tight enough but not too tight, as this may also cause damage.

Before beginning, check that your blade is sharp and has sufficient teeth per inch (TPI) for your material – for cutting plexiglass, you should use 4-6 TPI blades only.

Conclusion

In conclusion, cutting plexiglass with a jigsaw requires following a few key steps, but can ultimately be completed quite easily. With the right protection and materials, even novice DIYers can successfully complete this task. Knowing the dos and don’ts for cutting plexiglass with a jigsaw can help ensure that you’re able to make accurate and clean cuts every time.

Additionally, using the many variable speed settings on your jigsaw makes it easy to adjust the speed and power according to your material needs – providing you with an even better result in the end.

FAQS

How do I cut plexiglass without cracking it?

You can cut plexiglass without cracking it by using the proper tools, such as a sharp blade or a cutting tool specifically designed for plexiglass, and by applying even pressure throughout the cut.

What is the proper way to cut plexiglass?

The proper way to cut plexiglass is to use a sharp blade or a cutting tool specifically designed for plexiglass, and to apply even pressure throughout the cut. It is also important to use proper safety equipment, such as eye protection and gloves.

Can I use a jigsaw to cut plexiglass?

Yes, a jigsaw can be used to cut plexiglass, but it is important to use the proper blade and to cut slowly and carefully to avoid cracking or chipping the material.

What is the best jigsaw blade for cutting plexiglass?

The best jigsaw blade for cutting plexiglass is a fine-toothed blade with a high tooth count, such as a TPI of 10 or more. This will help prevent chipping and cracking during the cut.

How do you cut plexiglass with a jigsaw at home?

To cut plexiglass with a jigsaw at home, use a fine-toothed blade with a high tooth count, such as a TPI of 10 or more. Cut slowly and carefully, and apply even pressure throughout the cut. Use proper safety equipment, such as eye protection and gloves.

Does plexiglass crack easily?

Plexiglass can be prone to cracking or chipping if it is not cut or handled properly. However, it is generally more resistant to impact and shattering than glass.

What causes plexiglass to crack?

Plexiglass can crack or chip if it is cut improperly, exposed to high heat or cold temperatures, or subjected to impact or pressure.

What are the negatives of plexiglass?

Some of the negatives of plexiglass include its tendency to scratch easily, its susceptibility to cracking or chipping if not handled properly, and its lower resistance to UV radiation compared to glass.

What damages plexiglass?

Plexiglass can be damaged by exposure to high heat or cold temperatures, exposure to UV radiation, scratching or scraping, and impact or pressure.

What is the lifespan of plexiglass?

The lifespan of plexiglass can vary depending on its exposure to UV radiation and other environmental factors. Under normal conditions, it can last for many years without yellowing or becoming brittle.

See Also:

- Best dewalt jigsaw

- Best jigsaw blade for laminate countertop

- Best jigsaw blade for mdf

- Best jigsaw blade for plexiglass

- Best jigsaw blade for vinyl plank flooring